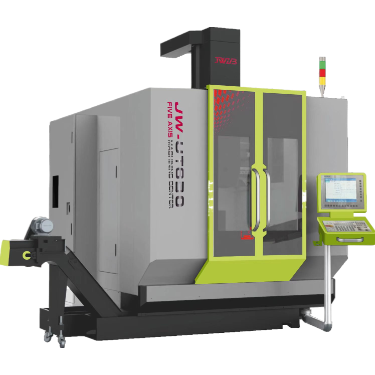

1.Main features of the machine tools

- The main shaft box and other key components adopt high quality TH 300 castings. The reasonable structural strength is calculated and analyzed by finite element analysis to provide high mechanical rigidity. Casting structure adopts integrated molding technology box structure machine tool has high rigidity and high strength geometric positioning accuracy is excellent. And can ensure the long-term stability and high precision.

2.The base is wide, the column is a box structure, the saddle is widened and lengthened, the heavy load full support design, the structure is solid, which can ensure the heavy load capacity during processing.

3.The spindle box is reinforced with ribs, and the contact length ratio between the spindle box and the column is appropriate to provide stable support for the spindle.

4.Three-axis motor and precision high-speed ball screw direct drive, enhance rigidity and improve precision.

5.The three axes adopt roller linear guide rail, which has the characteristics of high rigidity, low noise and low friction, and can do fast displacement and obtain the best circular accuracy.

6.The cutting fluid capacity is large to discharge the cutting heat quickly. The water tank is L type and placed on both sides of the machine to save space.

7Fast, simple, reliable and long life tool exchange device to provide stable and reliable tool exchange. Unique tool switching device design, advanced cam type drive mechanism, arbitrary position knife selection ability, can be quickly controlled by PLC software. The knife changing mechanism has been tested for one million times and meets the reliability requirements. Quick knife mechanism saves cutting time and improves production efficiency. The cam-driven knife library ensures high-precision rotation and runs smoothly with heavy-duty tools.

8.The spindle standard rotation speed is 8,000 rpm. Standard machine set uses large horsepower spindle motor. Spindle and motor belt connection greatly reduce the transmission noise and heat generation. The spindle uses G-TECH GT-5052A dynamic balance correction equipment to directly correct the spindle dynamic balance online, so that the spindle can avoid resonance phenomenon at high speed and ensure the best machining accuracy. Belt 10000 rpm, straight junction 12000 rpm spindle for high speed cutting (optional).

9.Use high strength and toughness four-flap claw pull knife, large contact surface, strong grasp force, small handle pull nail loss, long life.

10.The electrical box adopts the rear hanging design to save the space, make the limited space and obtain the maximum use.

2﹒Mechanical specifications

| model number | unit | JW-M1380 | |

| operating floor | tablesize | mm | 1500*800 |

| Maximum load bearing | kg | 1000 | |

| T-type slot (width x number x spacing) | mm | 18x5x150 | |

| Table Travel | X axis itinerary | mm | 1300 |

| Y axis itinerary | mm | 800 | |

| Z axis itinerary | mm | 700 | |

| principal axis | The distance from the main shaft nose to the work table | mm | 150-850 |

| Distance from the spindle center to the pillar | mm | 860 | |

| main shaft speed | rpm | 8000 | |

| taper hole of spindle | Type | BT-50 | |

| Spindle transmission mode | – | Belt spindle | |

| Automatically change the knife | Maximum tool diameter (no adjacent knife) | mm | Φ80(Φ130) |

| Maximum tool length | mm | 300 | |

| Tool selection | Random knife selection | ||

| knife handle | Type | BT-50 | |

| Knife library capacity | Pieces | 24 | |

| Tool exchange | – | 刀臂式 | |

| Tool exchange time (knife to knife) | Sec | 2.3 | |

| Motor capacity | controller | SYNTEC 22MA | |

| spindle motor | kW | 18.5KW | |

| Seromotor (X / Y / Z) | kW | 5.9/5.9/5.9 | |

| automatic lubrication installation | w | 20 | |

| Cutting liquid pump | w | 750-2 | |

| Power capacity | kVA | 35 | |

| other | Air source pressure requirements | kg/cm2 | 6/8 |

| Cut tank capacity | L | 200 | |

| positioning accuracy | mm | ±0.005/300 | |

| positioning accuracy | mm | ±0.003/300 | |

| Floor area and height | mm | 3300*3200*3300 | |

| Machine tool weight (approx.) | kg | 8500 | |

- 3. Host standard equipped

1.SYNTEC 22MA control system

2.Spindle cone hole blowing

3.Cutting blowing function

4.Cutting of the coolant system

5.Full cover cover

6.Automatic lubrication system

7.Foundation bolts and cushion blocks

8.Toolbox and Tools

9.work light

10.Operation status indicator light

11.Mobile hand-shake pulse generator

12.Hand hand blowing air gun

13.The machine washes the water gun

14.Mechanical, electrical, and operation instructions

15.Rigid attack teeth

16.Electrical box heat exchanger

17.transformer

18.Manual pine knife device

19.Automatic tool switching system

20.Three-axis slide rail telescopic shield

21.Z-axis nitrogen gas counterweight

- 4. Random attachment

| P / N | name of a part | specifications | quantity |

| * | hold-all | A set | |

| △ | manual of operation | 1 | |

| △ | circuit diagram | 1 | |

| △ | Random accuracy table | 1 | |

| ☆ | Basic supplies | A set |

Note: with “*” for adjustment tool; with “△” for technical manual; with “☆” for random parts

5﹒Main zero unit manufacturers

| order number | name | specifications and models | country of origin | manufacturer |

| 1 | numerical control system | SYNTEC 22MA | Taiwan, China | SYNTEC |

| 2 | spindle motor | 18.5kW | Taiwan, China | SYNTEC |

| 3 | X、Y、Z Axis motor | 5.9/5.9/5.9 kW | Taiwan, China | SYNTEC |

| 4 | Change the knife-tool manipulator structure | Cam-type BT50-24T | Taiwan, China | Speedcn |

| 5 | ball screw pair | Φ40/12 | Japan | THK |

| 6 | Rolling bead wire bar bearing | 30TAC62B | Japan | NSK/FAG |

| 7 | Linear guide rail | X:45*3

Y:45*2(4 lead rail ) |

Japan | THK |

| 8 | principal axis | BT-50-8000RPM | Taiwan, China | Speedcn |

| 9 | electrical apparatus element | France | Schneider |