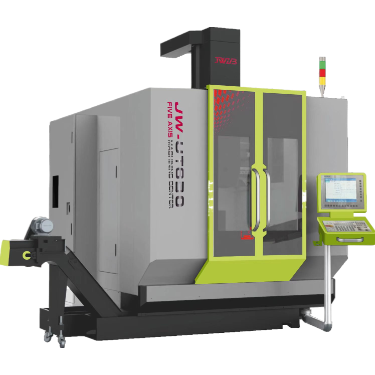

- Machine Structure

| Bed Construction:

1.This series represents our mature domestic/export product line, featuring compac structure, ergonomic design, high-torque spindle, exceptional rigidity, stable performance, and superior long-term accuracy retention. 2.The optimized head stock design accommodates both disc-type and shaft-type workpiece machining, capable of linear/arc interpolation, metric/imperial threading, and multi-start threading. Ideal for complex geometries and high-precision components. 3.Machine bed and saddle utilize specially formulated hardened guideways with high-frequency quenching, delivering ultra-wear resistance and prolonged accuracy stability. |

2.Technical Specifications

|

Parameter |

Unit |

Value | ||

| CK61125 | ||||

| Swing Over Bed | 毫米 | Φ1250 | ||

| X-axis Guideway Span | 毫米 | 330 | ||

| Z-axis Guideway Span | 毫米 | 700 | ||

| Max. Turning Diameter | 毫米 | Φ850 | ||

| Max. Machining Length | 毫米 | 1500 | ||

| Distance Between Centers | 1700 | |||

|

Center

Height |

Center Height Above Bed Ways |

毫米 |

630 |

|

| Height from Floor |

毫米 |

1450 |

||

| 主轴 Bore Diameter | 毫米 | Φ130 | ||

| Bar Capacity | 毫米 | φ125 | ||

| 主轴 Nose | A2-11 | |||

| Chuck Specifications | 毫米 | Standard φ800 4-Jaw Chuck Specifications | ||

| Spindle Taper Specifications | No | Metric120, 1:20 | ||

| Spindle Speed Range | 转速 | 30-84,53-150,125-350,300-835r/min

4-Speed Stepless Transmission within Ranges |

||

| Tail stock Quill Diameter | 毫米 | φ 130 | ||

| Tail stock Quill Taper Specifications |

No |

MT6# |

||

| Tail stock Quill Travel | 毫米 | 265 | |

| Tail stock Type | Manual hand wheel-operated | ||

| Number of Tool Stations on

Electric Turret |

Unite |

4 |

|

| Tool Holder Square Size | 毫米 | □32 ×32 mm (4-station turret) | |

|

Ball screw Models |

X 轴 | FYND4006-3-P3 | |

| Z 轴 | FYND6310-5-P4 | ||

| X/Z-axis Rapid Traverse Speeds |

m/min |

4/5 |

|

| X-axis Travel | 毫米 | 625 | |

| Z-axis Travel | 毫米 | 1500 | |

| Minimum Command Unit | 毫米 | 0.001 | |

| Main 主轴 电机 Power | KW | 22(VF drive) | |

| X/Z- axis Servo Motor Torque Specifications |

N.M |

10/22 |

|

| Total Power Supply Capacity | KW | 30 | |

| Machine Net Weight

(Approximate) |

Kg |

6500 |

|

| 机器尺寸

(L×W×H) |

毫米 |

4500x2200x2200 |

|

Important Notes:

Chuck/Fixture Installation:

Observe the maximum rotational speed limit of the selected chuck or fixture

Power Supply Requirements:

Strict voltage stability is required (±10% tolerance).

A voltage stabilizer must be installed if grid fluctuations exceed this range to

prevent operational failures or unpredictable outcomes.

- Standard Configuration

|

Component |

规格 |

Qty |

品牌 |

起源 |

| 数控系统 | GSK988TDi | 1 set | GSK CNC | 国内 |

| Spindle Motor | 22KW (VF) | 1 set | Nanjing Huanqiu | 国内 |

| Spindle Structural Specifications | Precision assembly | 1 set | Self-made | 国内 |

|

Main shaft bearing |

NN3032K/W33P5;234432M/SP

NN3026K/W33P5 |

1 set |

Tianjin

Nine/Wafangdian |

国内 |

| Guide rail | Hard rail | 1 set | Self-made | 国内 |

|

X-direction ball screw |

FYND4006 |

1 set |

Nanjing aftsman ship |

国内 |

| Z-direction ball

screw |

FYND6310 |

1 set |

Nanjing |

国内 |

| X-direction lead

screw bearing |

BS2562/P4DB;6205 | 1 set | Two-axis | 国内 |

| Z-direction lead

screw bearing |

BS4090/P4TBT;BS4090/P4DT | 1 set | Two-axis | 国内 |

| Knife rest | HAK-21 280 | 1 set | Hongda | 国内 |

| Automatic

lubrication device |

RBCLB-3ZK |

1 set |

国内 |

|

| Four-prong

manual single |

K11 800 |

1 set |

Wafang dian |

国内 |

| Cooling pump | 1 set | 国内 | ||

| Optional: Hydraulic unit | 60L | 1 set | 国内 | |

| Optional: Hydraulic chuck | KT12-3/ KT15-3 | 1 set | 国内 |

4 . Included Documentation & Accessories:

| No. | 项目 | Qty | 备注 |

| 1 | Packing list | 1 | set |

| 2 | Certificate of Conformity (including Precision Inspection sheet) | 1 | set |

| 3 | User Manual | 1 | set |

| 4 | Instruction Manual of Numerical Control System | 1 | set |

| 5 | Instruction Manual for Electric Tool Rest | 1 | set |

| 6 | Frequency Converter Instruction Manual | 1 | set |

| 7 | Motor Instruction Manual | 1 | set |

| 8 | Driver Instruction Manual | 1 | set |

| 9 | Oil Pump Instruction Manual | 1 | set |